Forklifts are critical pieces of equipment in several industries, including manufacturing, construction, warehousing, and logistics. They are used to safely and efficiently lift and transport big objects and commodities. Yet, operating a forklift may be a dangerous task, and accidents can occur without proper training and certification, resulting in injuries, fatalities, property damage, and costly litigation. In this post, we’ll look at the significance of forklift operator certification and training, as well as the benefits, standards, and best practices.

Forklifts are critical pieces of equipment in several industries, including manufacturing, construction, warehousing, and logistics. They are used to safely and efficiently lift and transport big objects and commodities. Yet, operating a forklift may be a dangerous task, and accidents can occur without proper training and certification, resulting in injuries, fatalities, property damage, and costly litigation. In this post, we’ll look at the significance of forklift operator certification and training, as well as the benefits, standards, and best practices.

What is Forklift Operator Certification?

Forklift operator certification is a process that certifies an individual’s knowledge, skills, and ability to safely and successfully operate a forklift. Forklift manufacturers, industry associations, or third-party training providers often offer certification programs. Forklift operation and maintenance, safety requirements, load handling, and emergency procedures are among the topics covered in the training.

What Is the Importance of Forklift Operator Certification?

Picture explaining the full form of Occupational Safety and Health Administration (OSHA)

Compliance with Regulations

Certification for forklift operators is not only a best practice, but it is also a legal necessity in most countries. For example, in the United States, the Occupational Safety and Health Administration (OSHA) requires all forklift operators to be trained and certified before operating a forklift. Employers must give training and evaluate each operator’s performance to ensure that they are qualified to operate the forklift safely, according to OSHA. Noncompliance with these regulations can result in substantial fines, penalties, and legal responsibilities. In some situations, it may also result in the suspension or revocation of the company’s operating license.

Reduced Risks of Accidents and Injuries

Forklifts are powerful devices that can cause catastrophic injury if not used properly. If the forklift tips over, collides with other objects, or drops its load, an accident can occur. Such accidents can have serious repercussions, resulting in injuries, fatalities, and property damage. Furthermore, accidents might result in lost production, increased insurance rates, and legal fines.

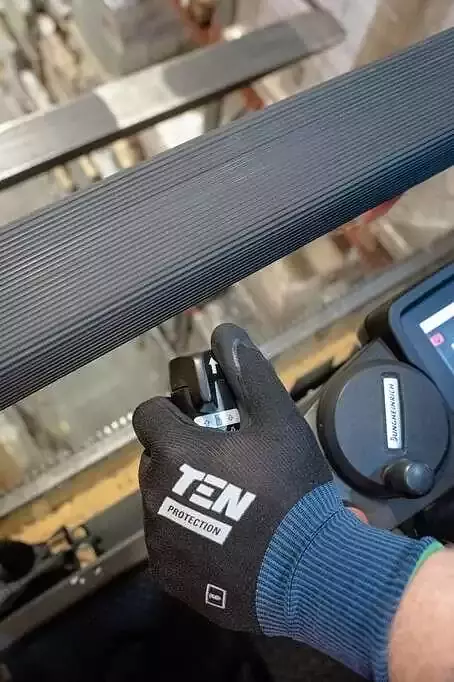

However, the danger of accidents and injuries can be greatly decreased if the operator is properly taught and certified in forklift operation. Understanding the forklift’s capacity, balancing the load, and maintaining safe operating speeds are all part of proper training. Furthermore, operators should get training in hazard detection, emergency procedures, and the proper use of personal protective equipment (PPE). By adhering to these best practices, the operator can reduce the likelihood of accidents and injuries while also protecting themselves and their coworkers.

Increased Productivity and Efficiency

Qualified forklift operators outperform untrained operators in terms of productivity and efficiency. This is because qualified operators have received rigorous training and are educated about forklift safety and operation. They know how to properly operate the forklift, balance the weight, and maintain safe operating speeds. This enables individuals to do their work faster and more safely, enhancing their productivity and efficiency.

Qualified operators also have a greater awareness of their work environment and the industry in which they work. They can recognize possible hazards and change their work methods accordingly, resulting in a safe and efficient workplace. This greater awareness results in a smoother workflow, fewer delays, and increased throughput, all of which result in cost savings for the organization.

Increased productivity and efficiency contribute to higher levels of customer satisfaction. Because forklift operators can move more goods in less time, they can meet client requests more quickly and efficiently. Customers are happy as a result, and they are more inclined to return for future business.

Lowering the cost of maintenance and repairs

Qualified forklift operators can help the organization save money on maintenance and repairs. Correct forklift operation and maintenance are crucial for extending its lifespan and avoiding costly repairs and replacements. Qualified operators understand how to execute common maintenance chores including monitoring fluid levels, tire pressure, and brakes, which can help to prevent equipment failure and costly downtime.

Qualified operators can also spot possible problems before they become big concerns. They are trained to identify symptoms of wear and tear, malfunctions, and other issues that may affect the functionality of the forklift. By detecting these issues early on, operators may collaborate with the maintenance team to resolve them before they become serious concerns. By preventing unexpected failures and repairs, you can save a lot of time and money.

Improved Employee Morale

One of the primary advantages of forklift operator certification and training is improved staff morale. Qualified operators feel a sense of success and pride in their talents, which can boost job satisfaction and drive. They are more confidence in their abilities to drive the forklift safely and efficiently, which reduces stress and improves job performance.

Employees that are confident in their talents are more likely to succeed and take pride in their work. This sense of accomplishment can lead to higher levels of job satisfaction and a more positive work atmosphere. Workers who are happy with their positions are less inclined to leave, lowering turnover rates and the expenses of acquiring and training new employees.

A happy work atmosphere can also boost overall productivity and efficiency, which benefits both the business and the employees. Workers that feel valued and appreciated are more inclined to go above and beyond their responsibilities and contribute to the company’s success. A poor work environment, on the other hand, can lead to increased stress, absenteeism, and decreased productivity, all of which damage the company’s bottom line.

How to Become a Certified Forklift Operator

Find a Training Provider

Choosing a Training Provider for forklift operator certification is an important step in ensuring that you receive excellent training that adheres to industry standards. You can choose a training provider from the forklift manufacturer, industry groups, or third-party training providers. It is critical to conduct research to ensure that the training company you select is credible and accredited. A good training company will teach you the skills and information you need to operate the forklift safely and efficiently. Furthermore, the training should meet the standards imposed by regulatory authorities such as OSHA.

Finish the Training

Finishing the training is a multi-step process that typically consists of classroom education, hands-on training, and a written test. The length of the training will vary based on the degree of certification you seek. Nonetheless, the training program normally takes a few days to a week to complete. You will learn about forklift operation and maintenance, safety standards, load handling, and emergency procedures during the course.

Hands-on training is essential in the certification process since it gives the operator practical experience with the forklift. The written test is intended to assess your comprehension of the training materials and ensure that you have the information required to operate the forklift safely and efficiently. To guarantee that you acquire the certification required to operate the forklift in your business, it is critical that you take the training seriously and devote time and effort into finishing the program.

Pass the Exam

You must pass both the written and practical tests to become certified. The written exam assesses your understanding of forklift operation, safety rules, and emergency procedures. The practical test assesses your ability to operate the forklift in a safe and efficient manner.

Get the Certification

After passing the examinations, you will be given a certificate of completion, confirming your forklift operator qualification. Your name, the type of forklift you are certified to operate, the date of certification, and the expiration date are normally included on the certificate. Certification is valid for a set length of time, usually three years, after which it must be renewed.

Forklift Operator Training Best Practices

Customize the Training for Your Industry

Training for forklift operators should be adapted to the unique sector and work environment. Each industry has its own set of hazards, laws, and working conditions, which must be addressed in training. A forklift operator in a manufacturing plant, for example, will require different training than one on a construction site.

Safety should be the number one concern in forklift operator training. Safety rules, hazard identification, and emergency procedures should all be covered in the training. Personal protective equipment (PPE) such as a hard hat, safety shoes, and a reflective vest should be always taught to the operator.

Offer Hands-on Practice

Forklift operator training must include hands-on experience. The operator should be able to practice using the forklift in a simulated work setting. This will allow the operator to become acquainted with the controls, as well as understand how to balance the load and build safe operating habits.

Regular Refresher Training

Forklift operator training is a continuous process. Operators should get refresher training on a regular basis to maintain their knowledge and abilities and to keep up with changes in rules and technology. After an accident or near-miss, refresher training can be provided.

Maintain Your Forklift Properly

Adequate forklift maintenance is crucial to maintaining safe operation. The operator should receive training on proper maintenance and inspection methods, such as monitoring fluid levels, tire pressure, and brakes. Any problems or difficulties should be reported to the supervisor or maintenance staff as soon as possible.

Conclusion

Certification and training for forklift operators are critical to ensure safe and effective forklift operation. Qualified operators are more productive, have fewer accidents and injuries, and spend less money on maintenance and repairs. Hands-on instruction, safety requirements, and emergency protocols are all part of proper training. Refresher training should be delivered on a regular basis to strengthen the operator’s knowledge and skills. Companies should prioritize worker safety and guarantee that all forklift operators are certified and taught to operate the forklift in a safe and efficient manner.